Wings 1

Wings page 1

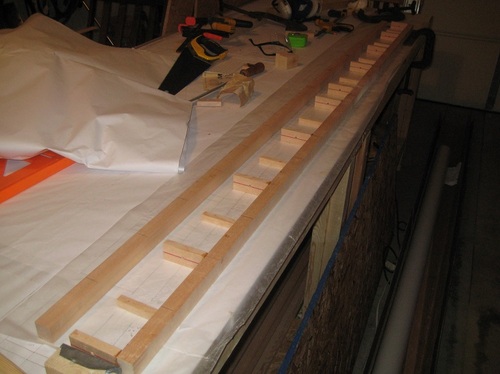

Wooden box spars are the bones of the wings. As you can see here, they consist of two long, thicker spar caps joined by smaller vertical pieces. These will be covered with thin plywood webs to form a very strong box structure. You have to make six units like this. The four outer spars taper to the tips, and are slightly more complex to build than the two center spars.

Notice the small holes drilled through the vertical pieces. After the inner chambers of the spars are closed up with the plywood skins, these small holes will allow the air pressure inside and outside the spars to equalize.

To test the strength of my glue joints, I purposely broke unused pieces of my spar caps with a hammer. If the piece breaks along the glue joint, you know you've mixed your epoxy wrong. This picture shows that the wood breaks, not the glue joint, so that's good. I'm using T-88 two-part epoxy and measuring the proportions to a tenth of a gram. It's incredibly strong epoxy. I'll keep some of the unbroken pieces in my plane through the years and check them regularly with a hammer to see whether the glue is weakening. If this KR is maintained properly, there's no reason it won't easily outlast my flying days.

Here's the jig, based on Mark Langford's setup, that I used to taper my outer spar caps. It enabled me to send the caps through my table saw at an angle. In this picture I have not yet secured the cap squarely in the jig, but I assure you that all my spars came out accurately using this method.

Here are five of my six spars waiting to be covered with 3/32" ply webbing.

Doing this served no practical purpose.

Here I'm applying the plywood webbing to create the final "box" product. I protected the insides of the spars with two coats of urethane before closing them up.